Kautz Tags

I had a run of bad casts trying to master the vacuum assist lost wax process. I have solved the problem. (I hope) The picture on the left is two separate Sterling silver castings I made last Sunday. As you can see they came out perfect. Happy, Happy.

The center is two tags I made using CAD, CAM and CNC. This is two separate versions as I was experimenting with the code. The owl is the family crest animal. The tags are about 1" x 2" x 1/8" and each weigh a few tenths of A gram over a troy ounce. About $17.00 of Sterling silver at today's rate.

The last picture is just a couple of geegaws I and my daughter made. The acorn cap is my daughter's. I think she is planning to make a glass bead for the nut part.

Bellering Idiot

I have a new passion that is growing out of my desire to be creating something very unique and artful. It is the making of small bells from silver, brass, bronze, bell metal, whatever works. My desire is to highly detail the bell as well as the decorative handle or top part. There are almost unlimited possibilities. I will be using lost wax as well as machining on my Taig Micro CNC mill and lathe.

I have a new passion that is growing out of my desire to be creating something very unique and artful. It is the making of small bells from silver, brass, bronze, bell metal, whatever works. My desire is to highly detail the bell as well as the decorative handle or top part. There are almost unlimited possibilities. I will be using lost wax as well as machining on my Taig Micro CNC mill and lathe.

The largest bell that I will be able to run on my Taig mill will be two inches in diameter at the wide end. That limitation is created because of the depth that I am able to go inside the bell. I have to allow room between the mill bed and the spindle face for how I hold the bell and the length of the milling bit so I can clear the end of the wax cylinder before I start the internal milling. I have only four inches between the spindle nut and the face of the bottom chuck mounted on the table. Half that distance is the total height of the bell if I have to use an up to two inch long mill.

The fact is that I will be making bells of smaller diameter depending on the ratio of bell diameter and bell height. So with a two inch diameter bell the ration is 1:1 (d:h). That will make a 1:2 ration bell a maximum diameter of one inch. I am thinking most standard looking designs will fall between those two ratios. But then I am not going to limit myself to any standard design. The only limit is that it has to fit on the machine.

There is one other design limitation and that is the wax master has to fit inside one of my casting flasks with enough room for the required investment thickness. There are many sizes of flasks available so it is not a critical design concern with the size masters I can make on the Taig mill.

I am planning for the top part of the bell to be a screw on assembly. That will give me absolute freedom to design whatever I want to finish off the top. The bell bottom becomes the support or base for whatever I design for the handle. That is another whole design area to explore.

The screw on handle also provides a way to design the clapper hanger inside the bell. That can be a machined part like a loop with screw threads. The hole drilled in the top of the bell can be smooth or threaded. I see the design coming together! The clapper can be a turned or a cast part.

I do need to start a design book with graph paper so I can sketch ideas to scale. When I have something I like then I can take it to the CAD and make the actual working drawings. In a few weeks I plan to have an example to show here. This category is sure to grow!

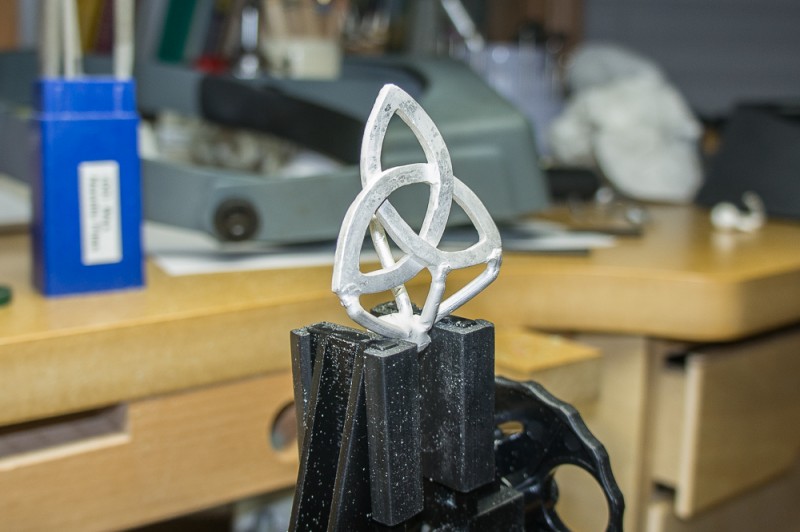

Celtic Trident Cross

I have created several Celtic theme silver Lost Wax Castings because they may look a bit complex, they are still rather easy to carve. I have also kept the pieces fairly large as that keeps it easy for me to hold in my hands.

This is the second carving of this design. The first one I did in green wax but it was lost in an incomplete cast. I made this duplicate in a couple of day and used Wolf's gold colored wax. It's a bit harder wax but that was not important in this second try.

You can see the wax and how it was sprued for investment. The next picture shows it after the cast and disinvestment. The last is with the jump ring installed and all polished up. The second picture where it looks all white is after it comes out of the acid pickle. It is totally clean and the white is how silver looks before it is polished.

Success

I am referring to lost wax casting in Silver.

It hasn't been a year yet but it is getting close. That’s when my adult daughter and I decided to take a course on wax carving and lost wax casting. We picked the training because it is something I have dreamed of doing for many years. What a joy to take the class together.

After that exposure I knew this was something I could really enjoy with my present health, keeping my hands and mind busy and being able to work while sitting down, for the most part. I decided and vowed to acquire all the tools to do the job at home.

I love hand tools and the detail work, and we bought what we needed to start the class. But now I also needed a few big items to do it all myself.

The first was the kiln that had to go to at least 1400 degrees. Of course I studied everything available. That’s part of the enjoyment, the education process. The Paragon (brand) kiln I bought will easily go to well over 2000 degrees. That gives me enough heat to try other high temperature crafts. This was the biggest expense. I think I invested well.

Next was the casting machine. Initially I was going to go centrifugal casting. I may still go there. But I definitely need a vacuum pump and chamber to degas the investment. There are some alternatives to vacuum degassing, but vacuum is the de facto standard. Plus it works with the vacuum assist casting process.

Centrifugal casting has been put on hold for now and my first good cast proves vacuum works. Of course I need a lot more good casts under my belt. I see clearly that centrifugal is the best choice for small lightweight and intricate casting. It is on my eventual want list. With centrifugal, the force is with me or at least works for me.

The last big hurtle was the comfortable place to do the many hours of wax carving. Since I brought it inside out of the Texas outdoor climate I am like a pig in a mud puddle, totally immersed in what I am doing and loving every minute of it.

Right now I am still refining my skills at wax carving. I will be exploring deeper in to CNC carving as my fingers start to misbehave. But I will take what I can get from my hands for as long as I can.

All the other investment in tools and material has come in small increments over the last 10 or so months. This first successful casting has a lot of time, effort and cost behind it. But all that will be amortized over a whole lot more production. It really isn’t the cost per item that I think about. It is all about the doing.

It demonstrates why handmade art does not and will not compete with mass production as far as cost per piece. The price of silver is only one factor in a long list of total value. Just knowing the person who has made an item adds tremendously to the intrinsic value. Owning something made by a factory assembly line is not the same fuzzy personal feeling as something produced by an artist, craftsperson or personal friend. For me as I have written elsewhere, I think what I make for family and friends provides an heirloom that includes a bit of spirit of the creator, me.

A Journey

I have just been doing a little wax work at my new, comfortable (air conditioned) wax work bench. I don’t think I will be calling it just wax “carving” as I am beginning to see what can be done with a little controlled wax melting. I am so pleased to see my knowledge and skills expanding. There is …so much to do and try.

I have just been doing a little wax work at my new, comfortable (air conditioned) wax work bench. I don’t think I will be calling it just wax “carving” as I am beginning to see what can be done with a little controlled wax melting. I am so pleased to see my knowledge and skills expanding. There is …so much to do and try.

I have promised myself that this blog will not be the “how to” but will concentrate on the art and the creativity. I will show the tools and the beauty I see in the stages of the work. I see the stages in wax carving as being as much art as the finished piece. Even the tools are a form of art in perhaps their shape and how they are used.

The preliminary sketches are a form of art in my eye. That’s why I show them here. The creative process flows from the mind’s eye, to the sketch or drawing and through the hands to the tools and machines that shape the material to the dimensions of the finished piece.

Like dance and music where the process of performing is the art, the process of creating dimensional art is a form of art that perhaps only the artist privately enjoys. I intend through good photography and electronic media (this blog) to occasionally display things I see while I am working, that look interesting in whatever stage it grabs me and speaks to me. The beauty is in the journey of creation.

The step by step “how to” I will leave to Ramblin Dan’s Workshop or other places where I publish that sort of industrial process detail. In here it will be all about the art. …maybe. Only you can decide if it works for you.

My main supplier of art products, Rio Grande posts a tag line under my name in my product reviews that says, “Life is a journey”. Somehow they seem to know me.